- en

- de

Power Systems

In the Context of Digitization, Strategic Adaptation of Asset Management Offers High Potential for Economic and Technical Optimization.

Asset Management

Examples of Optimization Areas for Plant Management:

- Improvement of Key Technical Factors: Enhancing factors like availability, dynamics, and operating points through the integration of various energy sources, storage systems, and/or consumer assets.

- Monitoring and Control: Overseeing maintenance and repair projects to ensure optimal functioning.

- Error Analysis and Troubleshooting: Identifying and resolving issues through statistical evaluation of system availability.

- Visualization of Assets: Displaying the status of all assets at a glance, including maintenance and testing schedules—comprehensive maintenance engineering.

Communication & Process Control Technology

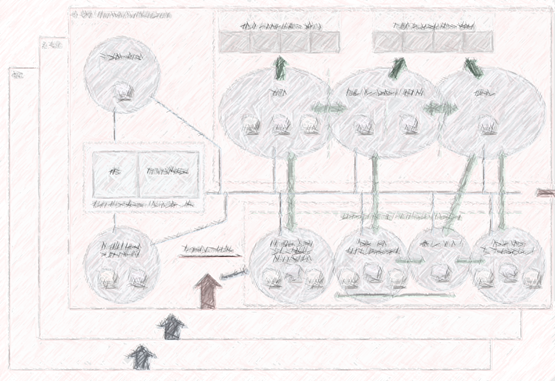

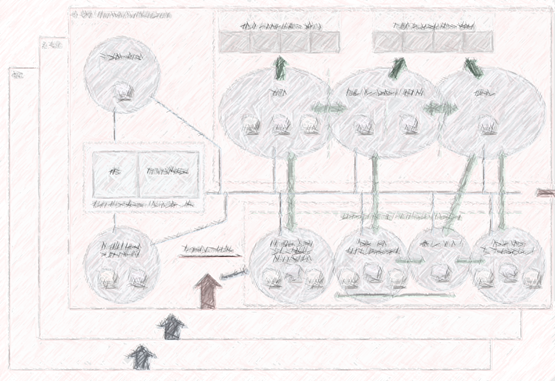

An essential component of complex production plants is their automation, control, operation, and monitoring systems.

As part of our projects, we guide our clients from process engineering through to the final implemented system. This includes defining process engineering tasks, converting them into manufacturer-neutral functional plans, and testing the functions of the control technology supplier after programming.

One of the challenges we address is the replacement of existing process control systems. We analyze the current system, develop strategies for replacing it, assess risks and opportunities, and create schedules based on relevant operational factors such as revision periods and system availability.

This knowledge enables us to create manufacturer-neutral inquiry specifications for potential control technology suppliers, which we prepare on behalf of our clients. We provide full support throughout the entire process—allocation, implementation, and acceptance.

A process control system also includes a control station, which should comply with current health and safety regulations. For the modernization of these control stations, we support our clients holistically as overall planners.

This includes not only visualization technology, but also architectural services, electrical engineering, lighting, heating/air conditioning/ventilation, and all other systems found in a control center. Together with our clients, we develop the optimal solutions.

Energy Management

The main objectives of energy management include:

- Optimization of Load Management: Adjusting plant operations and resource usage to improve efficiency.

- Development of Untapped Energy Efficiency Potentials: Identifying and harnessing previously overlooked energy-saving opportunities.

- Reduction of Energy Costs: Implementing strategies to lower overall energy expenses

- Minimization of Greenhouse Gas Emissions: Reducing harmful environmental impacts, including greenhouse gases.

- Optimization Considering Existing Potentials: Improving systems with respect to potential optimization goals (such as contract compliance and consideration of network bottlenecks).

The choice of energy management system depends on the size of the company and its objectives.

For Small and Medium-sized Enterprises:

- DIN EN ISO 50001

- EMAS System

- Energy Audit according to DIN EN 16247

Alternative System according to the Peak Balancing Efficiency System Ordinance (SpaEfV)

For Larger Companies:

- DIN EN ISO 50001

- EMAS System

Transfer Concepts and Municipal Heat Planning

In the context of the ongoing heat transition, we develop transformation concepts for municipal utilities and municipalities, as well as municipal heat planning (KWP), aligning with current funding guidelines. These projects are executed in a structured process:

- Project Management

- Aptitude Test

- Inventory Analysis

- Potential Analysis

- Target Scenario

- Implementation Strategy with Measures

- Documentation of Results

- Public Participation

This approach ensures a comprehensive, actionable roadmap for municipalities and utilities navigating the energy transformation.

Together with our partners ENEKA and ENERTECH, we have successfully implemented numerous projects featuring digital twins in recent years.

ENEKA. Energy planning is already operational in approximately 300 municipalities, supporting application cases such as municipal heat planning, energy-efficient district concepts, and climate protection strategies.

Renewable Energy: Hydrogen Technology

We offer a comprehensive consulting and engineering package for hydrogen production plants, including:

- Basic Determination: Defining the company’s goals and establishing the framework for hydrogen projects.

- Concept Planning and Feasibility Studies: Developing detailed plans and conducting feasibility studies with cost estimates.

- Electricity Generation Using Renewable Energies: Utilizing renewable energy sources for hydrogen production.

- Hydrogen Production Through Electrolysis: Implementing electrolysis technology for sustainable hydrogen production.

- Conversion and Storage of Hydrogen: Planning for the efficient conversion and storage of hydrogen.

- Transporting Hydrogen: Solutions for the safe and efficient transport of hydrogen.

- Energy Generation Through Fuel Cells: Integrating fuel cells for energy generation using hydrogen.

- Factory Transformation with Hydrogen: Assisting in the transition of factories to hydrogen-powered systems.

- Alternatives to Hydrogen: Offering alternatives to hydrogen for climate-friendly factory transformation.

- State Funding: Providing advice on available state funding opportunities, requirements, and criteria for hydrogen-related projects.